Retail supply chain would be impossible to imagine without wholesalers – a booming market in its own right, expected to surpass $61 billion by 2027. Today we will talk about who they are, what sets them aside from manufacturers, distributors, and retailers, and how a wholesale supply chain can reach new heights.

On the path that goods take through the supply chain, wholesalers are an important companion. While some businesses buy their products directly from manufacturers, others use wholesalers – the middlemen in this process, buying goods fresh off of conveyer belt and delivering them to retailers.

Do not confuse them with distributors. Supply chain distribution, also known as allocation, is the term for distributing merchandise from the manufacturer to retail locations. It seems similar to wholesale, but distributors in supply chain are specific to a certain territory with its unique trends.

There are several types of entities that operate as wholesalers. All of them go about their wholesale planning and distribution a little differently. Shopify points out these three categories:

- Merchant wholesalers. This approach is the most popular. A company buys goods in bulk from manufacturers, stores the goods in its warehouses, breaks up the sum total of goods into smaller batches, and sells them to final retailers. This category neither produces nor retails the goods themselves.

- Agents. Agent, or a broker, is an independent intermediary who functions much the same as wholesalers do for consumer goods. They do not buy and own the manufacturers’ goods; just strike up the deals between manufacturers and merchant wholesalers from the first category, simplifying the process for them for a fee.

- Distribution teams. These teams consist of non-independent brokers on manufacturer’s payroll. They are fully integrated into the manufacturer company to do wholesale management, although their office is usually separate from the plant.

Using a wholesaler removes a lot of stress from both manufacturer and retailer. Let’s take a look at the most well-known wholesaler benefits:

- Increased efficiency. Wholesalers often have a larger inventory and distribution network, allowing them to efficiently manage and deliver products.

- Convenience. Wholesalers handle logistics, storage, and delivery, freeing up retailers’ time and resources.

- Expert knowledge. Wholesalers often have product knowledge and can provide advice on usage, compatibility, and applications.

- Flexibility. Wholesalers may be able to accommodate special requests, such as custom orders or bulk purchases.

- Access to new products. Wholesalers may offer new or niche products not available directly from manufacturers.

Wholesale businesses are widespread and famous. Chances are, these examples of wholesalers will be familiar to you:

- Costco is a US-based membership-only wholesaler known for bulk products at discounted prices, ranging from groceries and electronics to furniture and appliances.

- Alibaba is a global online marketplace connecting businesses with suppliers offering wholesale products across various categories, enabling international trade and bulk purchases at competitive prices.

- DollarDays is another example of a wholesaler, catering primarily to retailers, nonprofits, and small businesses seeking discounted purchasing options.

An efficient supply chain looks like well-tuned processes, met bottom lines, and a prospering business as a result. On the surface, it might seem like it would be easy to tell whether a supply chain is efficient or not by just looking at these qualities. However, when it comes to scientifically measuring, and later improving supply chain efficiency, businesses need to utilize loads of data analysis and complex math.

The first step to improving something lies in understanding it. What is supply chain efficiency? It will be easier to define this term by comparing it to other, similar concepts.

Supply chain responsiveness is defined by one crucial metric: speed of reaction. Various disruptions, fluctuations, or, on the contrary, lucrative opportunities, demand a quick response from supply chains that don’t want to lose money. While responsiveness focuses on adaptability and flexibility in response to changing conditions, efficiency focuses on cost reduction and process optimization. Efficiency is often measured by cost-related metrics (e.g., cost per unit), while responsiveness is measured by speed-related metrics (e.g., time-to-market).

In practice, both efficiency and responsiveness are important for a well-performing supply chain. A supply chain that is highly efficient but slow to respond may struggle to adapt to changing market conditions. Similarly, a supply chain that is highly responsive but inefficient may struggle to maintain profitability.

Where efficiency focuses on optimizing internal processes, effectiveness focuses on achieving strategic objectives and delivering value to different stakeholders. This refers to meeting the expectations of investors, customers, and suppliers. Efficiency views the supply chain from the perspective of process optimization, while effectiveness views it from the perspective of customer satisfaction. Efficiency uses cost-related metrics (e.g., cost per unit), while effectiveness is measured by customer-focused metrics (e.g., customer satisfaction).

Now that you know what supply chain efficiency is, and is not, it is time to learn the correct metrics used to measure it. According to NetSuite, you should look at:

- Perfect order index. The percentage of flawless orders that arrived exactly on time, in top-notch condition, and with accurate paperwork.

- On-time deliveries. The frequency of orders arriving exactly when expected and scheduled, also known as service rate.

- Inventory turnover ratio. The number of times a company sells and replaces its inventory within a given period, typically a year. It’s calculated by dividing the cost of goods sold by the average inventory value, and is expressed as a ratio (e.g., 5:1).

- Order accuracy. The correctness of order information and the way it was delegated, in percent.

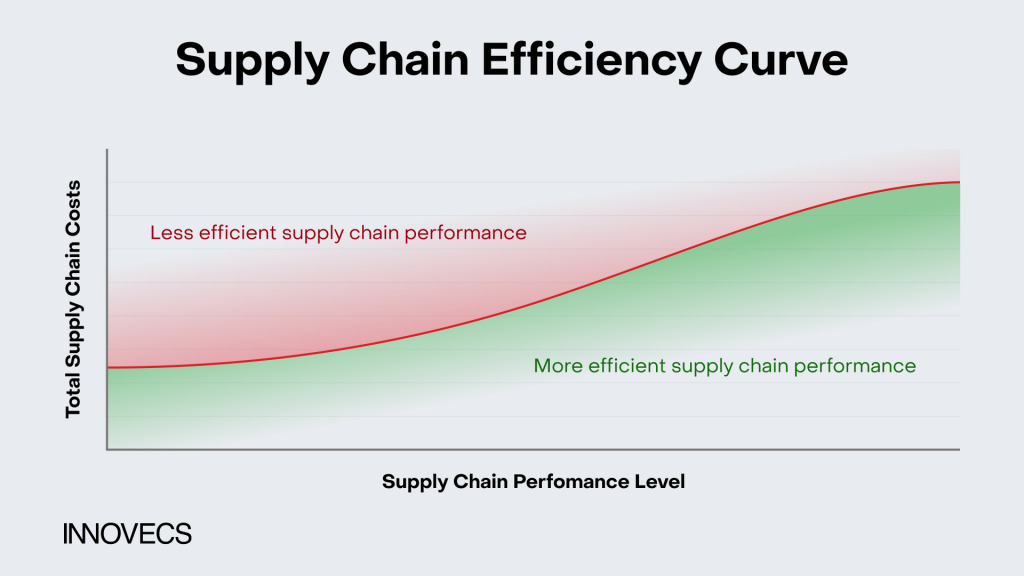

In addition to that, you could also use the supply chain efficiency curve.

This theoretical concept is used to describe and visualize the relationship between supply chain costs and efficiency. As supply chains become more efficient, costs decrease, but only up to a point, beyond which further improvements become increasingly difficult and expensive to achieve. The curve has three stages: inefficient supply chain (high costs, low efficiency), improving supply chain (decreasing costs, increasing efficiency), and optimal supply chain (high efficiency, low costs).

- Horizontal x-axis visualizes supply chain performance in metrics your company prioritizes.

- Vertical y-axis visualizes the costs your company spends on its supply chain.

The curve of an efficient wholesale company will be on the flatter side, with performance rising faster than the costs. Understanding this curve helps businesses prioritize efforts to improve their supply chain operations and make informed decisions about investments in process improvements.

- Offer competitive prices. Invest in calculating the maximum discounts you can grant to your biggest clients to attract more purchases without setting yourself back. It’s going to be a delicate balance between offering lower prices than your competitors and shooting your bottom line in the foot by going too far. This category also includes being transparent about your pricing model with your clients. The presence of last-minute hidden fees can affect your reputation.

- Ensure the high quality of your supply. High-quality inventory is going to be a crucial factor for client retention. This step includes multiple sub-categories:

- Optimize the design of your wholesale supply warehouse. A more intuitive layout of the warehouse means faster packing routes and safer supply. Small mechanic damages to your goods are impossible to fully eradicate: from forklifts bumping into stacks to distracted employees slipping and tripping, accidents happen. Take some time to minimize their chances before your perfect order index and your people suffer.

- Regularly update your temperature control practices. Temperature control is important for ensuring the quality and durability of most items, and is absolutely crucial when it comes to preserving perishable goods. Outdated temperature control systems can be a huge factor in not only your supply’s quality, but the general contributions of cold chain to the climate crisis, which, in turn, create more severe temperatures to tackle down the line. Do not contribute to the vicious circle; update your technology.

- Maintain and update your WMS and IMS. Inventory management and warehouse management are the two pillars of efficient warehousing, which is the fist step in your wholesale distribution management.

- Make your freight as transparent as possible. Lag-free GPS and digital checkpoints at every link of your wholesale supply chain will tighten your grip on the logistics and allow for great data gathering.

- Invest in data analytics. Relevant information, combined with client feedback, will tell you everything you need to know to improve your efficiency. Utilize automation in your data processing algorithms and use its findings for informed decision making and forecasting.

- Attend wholesale shows and conferences. In-person contact with your potential clients can provide you with many surprising insights and offer you a chance to establish a personal connection right from the start. These events also provide a great opportunity to assess, and learn from, your competitors.

What Is The Wholesaling Industry?

The wholesaling industry is a business that buys goods from manufacturers and then sells them to companies who do the actual smaller-scale retail. Wholesalers get the goods, store them, break up bulk orders, get them ready for sale, and drop the goods off where retailers need them. Having a distribution center between manufacturer and a retailer allows the retailer to carry less, and spend less time, money, and resources on preserving all of the goods on-site.

Why Large Companies Pay Less For Goods From Wholesalers?

Large companies often get such wholesale benefits because they can negotiate better prices through bulk purchases, preferred customer status, and contractual agreements. They may also benefit from reduced transaction costs, supply chain optimization, and purchasing power, allowing them to dictate prices and terms with wholesalers.

Why Can Wholesalers Offer Lower Prices To Larger Customers?

Just like it benefits the larger customers to get their goods cheaper, it also benefits the wholesalers to sell and drop off a large quantity of a certain item in one go. Sometimes, large customers can buy out the majority or even entirety of a certain stock. The transportation prices, freezing prices for cold chain goods, and pickup fees all decrease when they get divided by a big number.

Which Wholesaler Channel Function Helps Reduce Inventory Holding Costs?

This function is called consolidation. It combines smaller shipments from multiple suppliers into a single shipment, which reduces the number of times the goods need to be handled, stored, and transported, and therefore drives down the costs associated with these processes.

A Quick Response Delivery System Increases The Efficiency Of Which Process?

Quick response delivery system helps companies to better control their inventories, orders, and shipments. As an example of automation, it can increase the efficiency of many processes: inventory management, ordering process, reorders, deliveries, and more.